Perfectly adapted to process needs

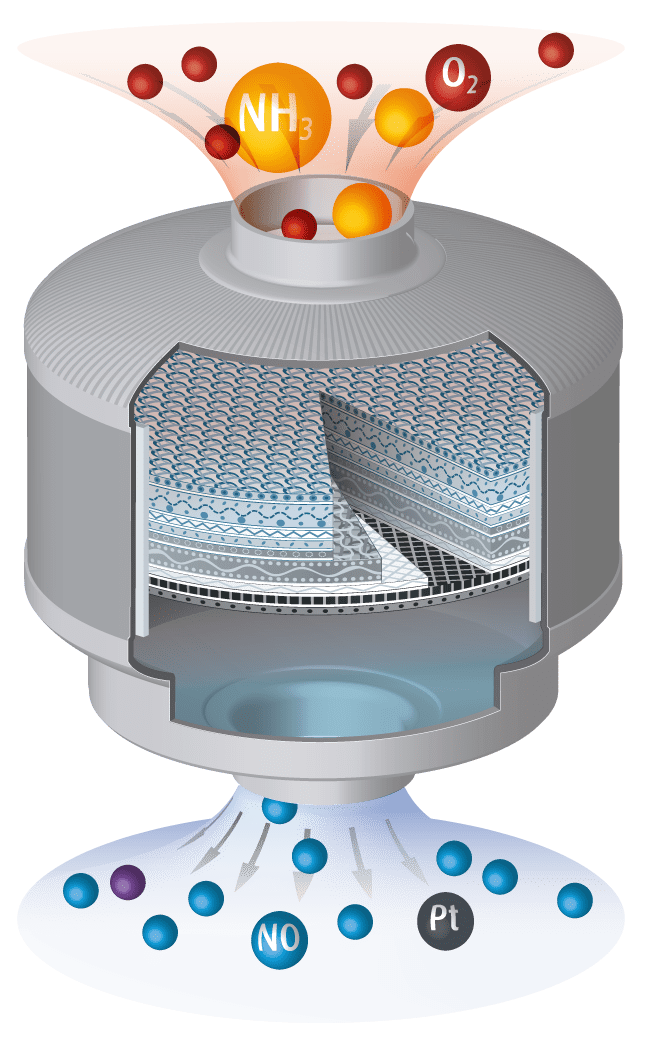

Two main factors are influencing the overall performance of gauzes in ammonia oxidation: Composition and Structure.

Our adapted flat-bed knitting technology has taken gauze designs many steps further by moving them into the 3rd dimension. All our gauzes, no matter if single- or multi-layer, are not just a conventional arrangement of wires like in any flat gauze, but are real three-dimensional structures. Dedicated amounts of wires are oriented out of the layer-plane resulting in optimized spatial arrangement to achieve maximum contact with the gas mix.

Find out more about our gauze families:

MPAC: Multi-Combination Gauze Pack

Tailored Effectiveness

Customized and fine-tuned adjustment of the gauze layer composition to the demands and the operational regime of any particular converter setting:

- Multi-functional gauze layers

- Multi-featured gauzes

- Functionalised separator gauzes

- Amplified catalyst & getter effectivity

- Adjustable gas flow & pressure drop characteristics

Process Excellence

Total Cost reduction by means of:

- Customized PGM weight

- Minimum primary losses of Platinum

- Remarkable reduction of ammonia consumption

- Improved oxidation yields

- Extended gauze life and campaign length

Find out more about MPAC