By providing highly selective and efficient ammonia oxidation solutions, we support a broad variety of final applications that require nitric oxide as precursor: nitrates for fertilizers to feed the world, nitrates for explosives to gain steel for building, hydroxylamines and methacrylates for any kind of plastics, or caprolactarme for clothing and fashion.

Find out more about:

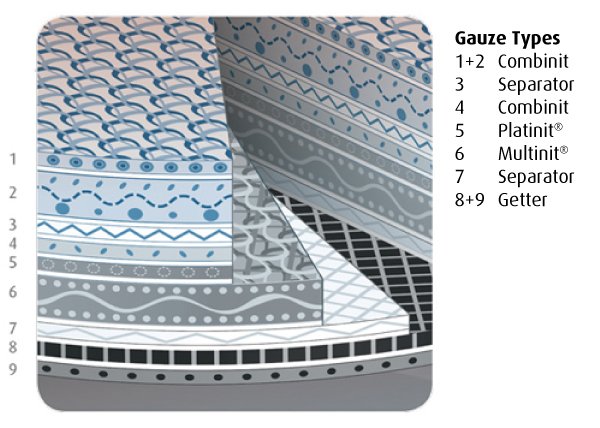

Multi-Combination Gauze Pack

A new gauze generation takes over catalytic ammonia oxidation: MPAC

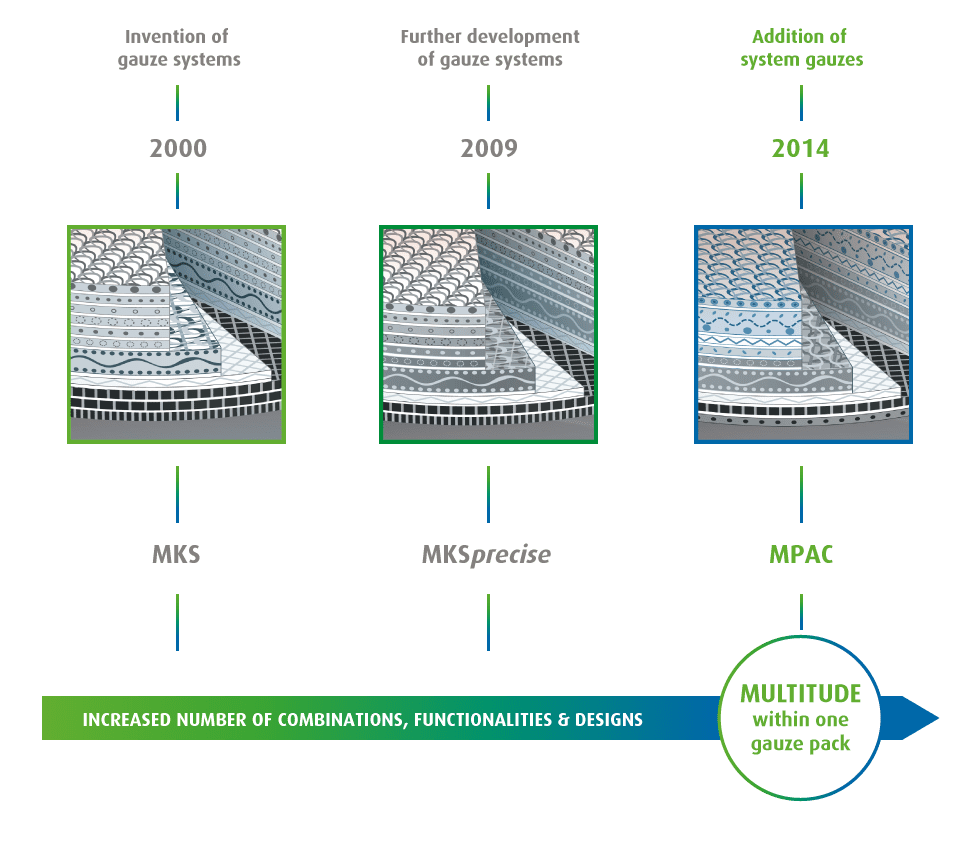

Multi-Combination Gauze Pack builds on the success story of the already unique multi-layer gauze systems that had been introduced more than a decade ago. A much broader toolbox of new and improved features supported by a much better understanding of how to use these tools enables gauze designs that will match significantly better with defined performance criteria in ammonia oxidation processes. The most striking difference compared to our established MKS systems is the fact that MPAC allows a distinctly bigger number of combinations, designs and functionalities. Next to material and wire constitutions it is first and foremost the structural uniqueness that makes MPAC an even more effective system compared to its MKS ancestors.

The first MPAC generation will focus on improving product yield, reducing PGM weight and increasing campaign times. For certain conditions it will also be able to lower greenhouse gas emissions.

Additional features & functionalities will be gradually added over the next 24 months, making MPAC a truly vital and dynamic gauze innovation.

Discover MPAC‘s features and your benefits!

Innovation

Originating from a tradition of innovation

MPAC vs. MKS

Significantly increased degrees of freedom

| Features | MKS | MPAC | |

|---|---|---|---|

| Hardware | Material species | 2 | > 6 |

| Wire classes | 1 | > 5 | |

| Pattern types | 3 | > 10 | |

| Software | Calculations | Basic | Sophisticated |

| Designs | Configurations | < 2.500 | >> 500.00 |

Benefits

Your benefits through improved funtionalities

- Installation Weight: Reduced PGM inventory

- Quick Yield: Rapid selectivity level

- Gauze Durability: Maximized process uptime

- Safety: Reduced operational risk

- Product Yield: Improved throughput & selectivity

- Tear Resistance: Superior mechanical gauze stability

- Built-in Reserve Capacity: Enabling additional load

- Process Understanding: Increased cause & effect awareness

- Operational Losses: Reduced PGM losses

- Problem Solving: Increase of competitiveness

- N2O Reduction: Choked emission levels

- Cost Saving: Lower total costs