What made us re-invent glass homogenisation devices...

Having been confronted with a wide range of comparable glass homogenisation problems that were common throughout the glass industry we observed that the performance of the conventionally used precious metal based homogenisation devices were not optimal due to their moderate effectiveness.

Consequently we defined the most urgent needs of glass producers and aligned them with the megatrends that drive the industry. Therefore our primary aim was to invent a device that would outperform all existing PGM stirrers used in various segments of the special glass industry.

In the first sketches originating from our development process, the arc blades were soon recognized as the most effective and striking design elements. When we studied the new device's glass agitation profile its extremely effective characteristic was unlike any other stirrer mode of action.

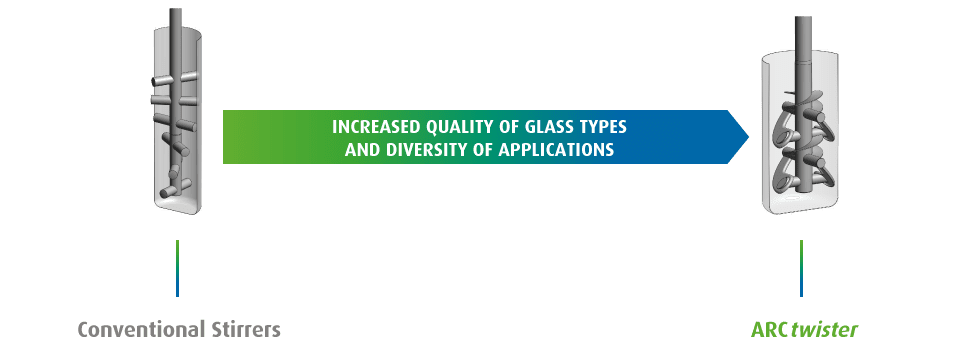

A new component for glass homogenisation was born: the twister. After its key design features we name it the ARCtwister.

Stirrer vs. Twister

Comparison 1: Effectivity in Glass Homogenisation

| Conventional stirrer | ARCtwister | |

|---|---|---|

| Volume Effectivity* | Partial | Complete |

| Contact frequency** | Medium | High |

| Flow behaviour*** | Reversible | Irreversible |

| Average distance**** | Short - medium | Long |

| Glas flow profile | Linear | Non-linear |

| * | Mass exchange throughout the entire relevant homogenisation space without any voids |

| ** | Glass particles in contact with the agitator elements within the volume per time unit |

| *** | In case of discrete homogenisation |

| **** | Trajectory of a glass particle / mass unit in a refernce volume element due to the flow characteristics |

Comparison 2: Features

Material |

Conventional Stirrer | ARCtwister |

|---|---|---|

| Main Material Type | Cast Alloy or ODS | FKS® |

| FKS ® Grades | 1* | 2** |

| FKS ® Sub-Grades | 0 | 2 |

Engineering |

Conventional Stirrer | ARCtwister |

| Software Tools | Basic | Advanced |

Designs |

Conventional Stirrer | ARCtwister |

| Base Types | 1 | 3 |

| Variations | < 25 | > 100 |

| TOTAL variants | < 25 | >> 1.000 |

| * | e.g. FKS® Rigilit® |

| ** | dedicated Twister grades |